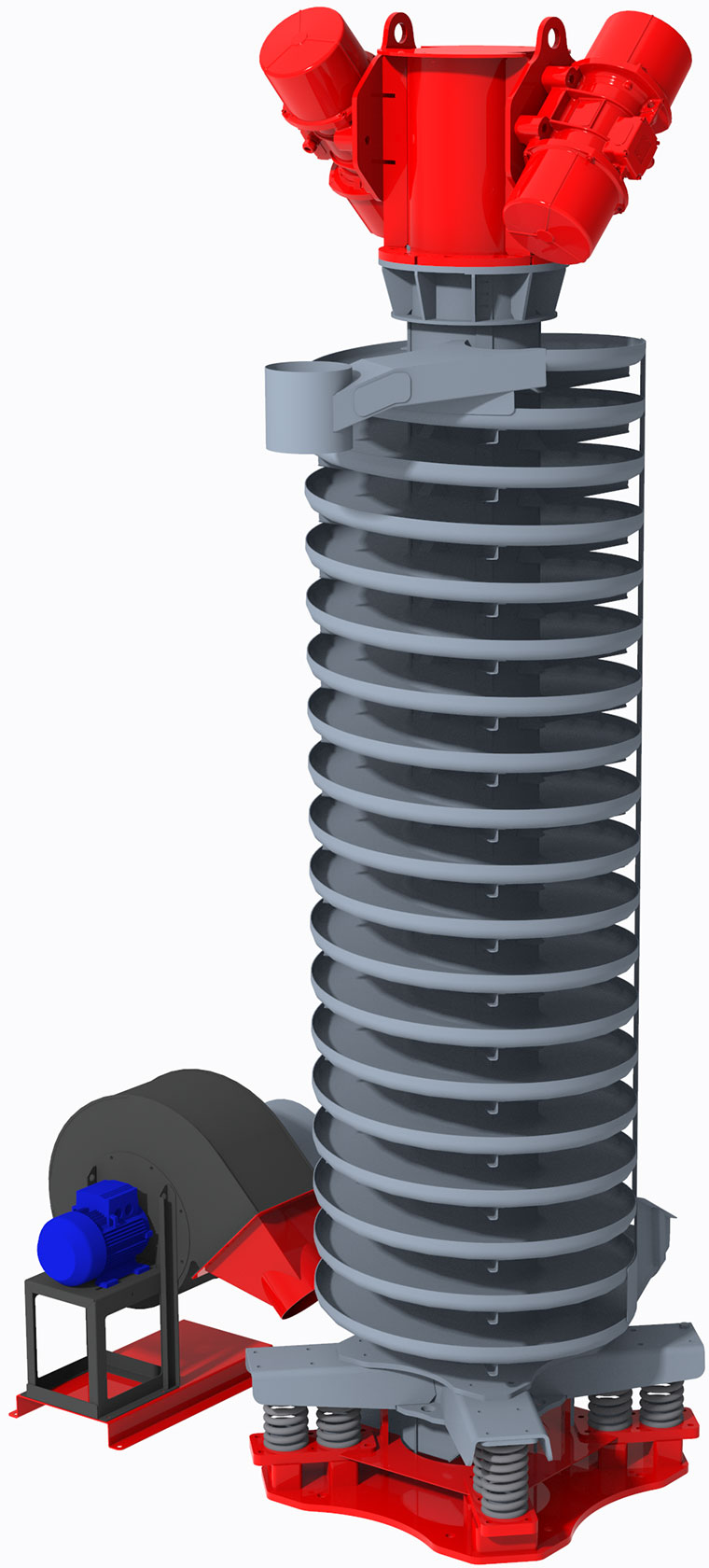

Spiral elevator model SVC

Throughput from 200 to 3500 kg/h

Spiral cooling system driven by vibrating motors are used to elevate bulk materials, ideal for materials such PA – PA6 – PA66 – PA 12 – TPE – TPU – PET sensitive to residual moisture after an o-ring or a water pellettizer.

The lift spiral series SVC is indispensable in the transport of all the materials that need to be elevated in height, cooled and/or heated.

Operation:

The construction of the apparatus consists of a helical track with a constant pitch housed and fixed on a central pipe support usually built in AISI 304.

The transport of materials trough an uphill motion produced by unbalanced motors which generate a boost oscillating amplitudes and frequencies subsidiaries.

The proper calibration of the motors and the robust construction of the machine makes that the material can be transported with a layer constant and that it can remain so throughout the path up to the discharge end.

This peculiarity makes the transported material can maintain a uniform layer and homogeneously distributed over the entire width of the conveying path guaranteeing, if need be, also needs a proper cooling, heating or evaporation.

Advantages:

– Inserting in narrow spaces thanks to the plan section of contained dimensions.

– Possibility of entering air blowers cooling or heating systems.

– Feed and speed of the material to be transported configurable through rapid changes in frequency to ensure the smooth progress of the different materials.

– Easy installation, low maintenance, quick cleaning and reduced downtime.