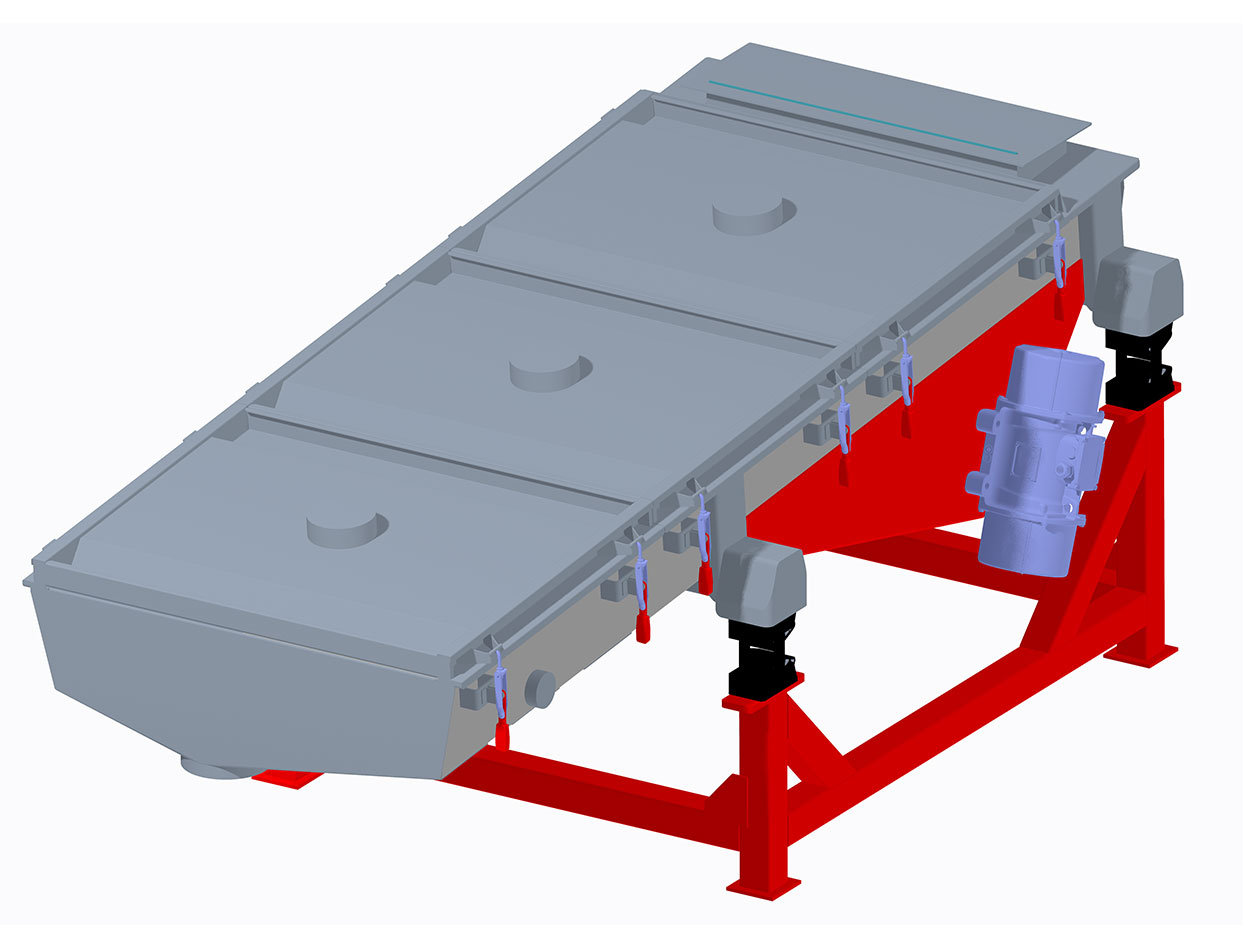

Rectangular sieve model RVS-L

Throughput from 0 to 10000 kg/h

The Rectangular vibrating screener RVS-L serves the purpose of separating, classifying, and ensuring the safety screening of both liquids and powders.

Its versatile dual functionality, encompassing both transportation and screening, makes it suitable for diverse applications, including plastic materials, food processing, urea, and more.

The dual motor setup induces a linear or straight-line vibration of the screens frame, perpendicular to the plane of the motors. Typically, the motors are positioned at an angle of 30/40 degrees relative to the screen surface. This arrangement facilitates excellent forward conveyance of oversize particles, even when the screens are positioned uphill.

By fixing two vibratory motors of the same frequency to a rigid common base, either freely suspended or supported, running in opposite directions, they automatically synchronize, generating a straight-line motion.

When this motion is applied to horizontal screens, it results in a horizontal action suitable for screening, conveying, and dewatering a wide range of products, particularly in spaces with limited headroom.

The rectangular screens can be customized by the factory to meet specific requirements concerning plant layout and environmental constraints. Please specify your particular needs or inquire about the available range of features, accessories, painting systems, and construction materials.

The cleaning operations are swift and efficient, thanks to the quick-release handles. Lids and screening plates weighing below 25 kg can be removed and replaced rapidly, which is advantageous when frequent color changes are necessary.

The noise level is kept below 75 dB for an empty machine, owing to the implementation of ROSTA elastic elements.

Modifications to the machine to suit your layout are possible, as our technical office is highly flexible and adaptable.